Alchemia’s facilities, approved by the Italian Medicines Agency (AIFA) are designed to satisfy a vast range of production requirements, from laboratory scale to one hundred kilograms per batch.

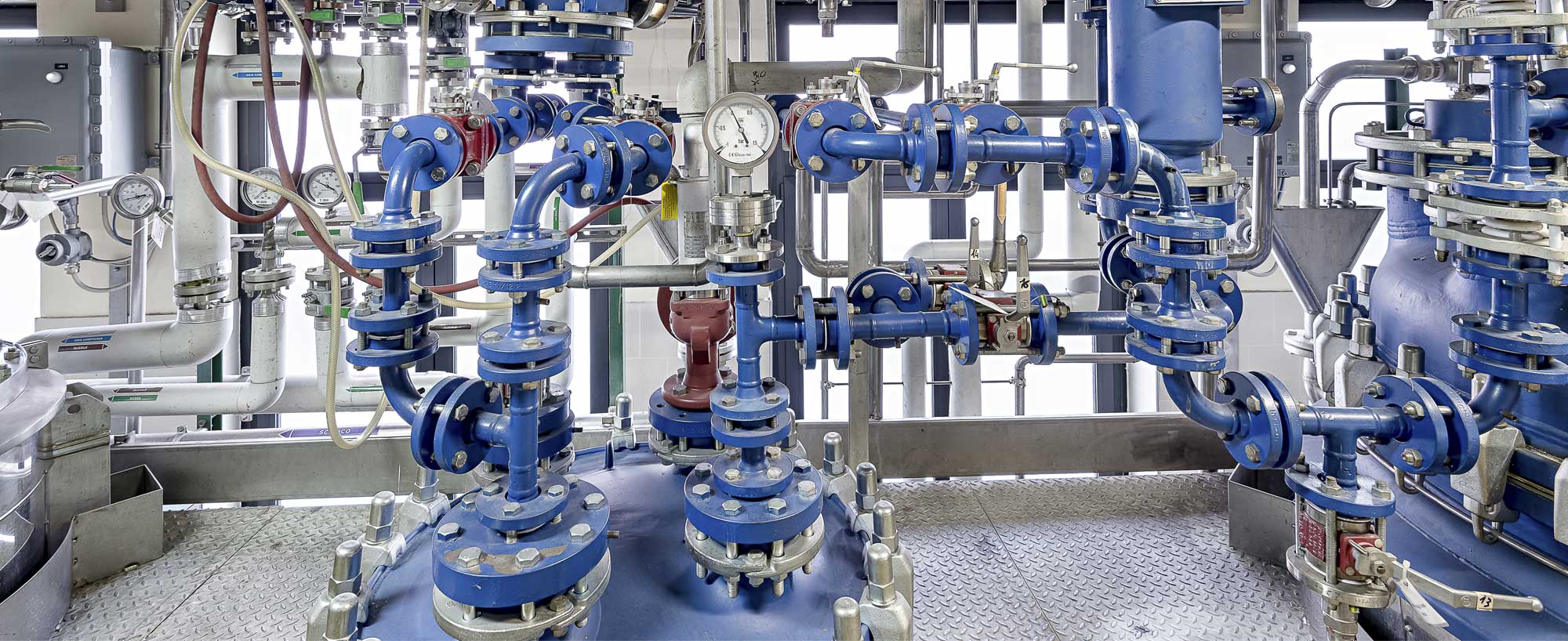

Our flexible facilities are well-suited to the production of complex, multi step products and include the latest high-tech manufacturing equipment which meets the highest standards of quality and safety.

Our expert team currently manufactures generic API’s in accordance to validated manufacturing procedures.

We focus on cost-effective manufacturing routes, without compromising quality.

From a technological standpoint the reaction typologies which can be performed at Laboratori Alchemia are virtually unlimited.

State-of-the-art technical equipment allows for operations at a very broad range of temperature (from -100°C to +250°C), pressure (from 0.1 mbar to 150 bar) and reaction volume (from lab equipment to 1,000-liter vessels).

Laboratori Alchemia carries out its activities with full respect for the environment, committing itself to preventing and limiting the possible negative impact deriving from its manufacturing processes.

The reaction typologies currently carried out at Laboratori Alchemia are as follow:

| Formation of Acylchlorides | Acylation | Alkylation | ||||

| Amidation | Amination | Bromination | ||||

| Condensation | Cyclization | Decarboxylation | ||||

| Dehydroalogenation | Esterification | Etherification | ||||

| Friedel Crafts reaction | Grignard reaction | Hydrogenation | ||||

| High pressure hydrogenation | Isomerization | Optical resolution | ||||

| Reaction with butyllithium | Reduction | Saponification | ||||

| Low temperature reaction |